INTRODUCTION TO THE BRAYTON CYCLE IN GAS TURBINES

The

purpose of this white papers on the Brayton Thermodynamic Cycle is to

provide a fairly non-technical introduction to the most important thermodynamic

cycle used in the gas turbine technology used by AscenTrust, LLC. (The Company)

in the design and installation of the first phase of the Nuclear

Technology Pebble Bed Modular Reactor (NTPBMR) prototype project. The NTPBMR power plant will eventually

use a very unique type of turbine cycle: The closed-loop, Brayton cycle helium

turbine. In order to realize this new

technology, the Company will first build conventional, natural-gas fired

power plants connected to an existing natural gas pipeline. Phase two will be to build conventional

natural-gas fired power plants powered by LNG (Liquid Natural Gas). Phase three of the project will consist of

building a combustion chamber to heat the helium to be used in a closed-cycle

turbine which will be design in our research and development center. The 55MWe

closed-loop, helium powered gas turbine, will then form the basis for the Balance

of Plant for the 110MWe helium-cooled, graphite-moderated, pebble bed

nuclear power plant.

In order to introduce

the operations of a gas turbine we will have to review some basic concepts of

thermodynamics which were developed in the days of Joules and Carnot and are of

interest to anyone who has an interest in understanding the processes

involved in the production of

electricity through the use of thermal energy.

The source of thermal energy is the subject of other white papers in

this series. The final resting place of

the source of thermal energy for our project is of course the production of

energy through the use of nuclear power. Inherent in any discussion of thermodynamics

is the requirement for a basic understanding of the structure of matter, and certainly in the discussion of the

production of electrical energy through the fission of nuclear material are

some of the topics of modern physics: Quantum Mechanics and Special

Relativity. Very little will be said

in this paper concerning these two vast topics of Physics and Engineering. Even the statistical nature of thermodynamics

will not be mentioned.

A gas turbine, also called a combustion turbine, is a rotary

engine that extracts energy from a flow of combustion gas. The main components

of a gas turbine are: an upstream compressor coupled to a downstream turbine,

and a combustion chamber in-between. Energy is added to the gas stream in the

combustor, where fuel is mixed with air and ignited. In the high pressure

environment of the combustor, combustion of the fuel increases the temperature.

The products of the combustion are forced into the turbine section. There, the

high velocity and volume of the gas flow is directed through a nozzle over the

turbine's blades, spinning the turbine which powers the compressor and, for

some turbines, drives their mechanical output. The energy given up to the

turbine comes from the reduction in the temperature of the exhaust gas. Energy

is extracted in the form of shaft power, compressed air and thrust, in any

combination, and used to power aircraft, trains, ships, generators, and even

tanks.

SECTION ONE: CHARACTERISTICS OF THE BRAYTON CYCLE

1. INTRODUCTION: The Brayton

cycle was first proposed by George Brayton for use in the reciprocating

oil-burning engine that he developed around 1870. Today, it is used for gas

turbines only where both the compression and expansion processes take place in

rotating machinery. Both the compressors and the turbine are axial machines.

Gas turbines usually operate on an open cycle, as shown in

Fig. 1.1 below. Fresh air at ambient conditions is drawn into the compressor,

where its temperature and pressure are raised. The high pressure air proceeds

into the combustion chamber, where the fuel is burned at constant pressure. The

resulting high temperature gases then enter the turbine, where they expand to

the atmospheric pressure while producing power. The exhaust gases leaving the

turbine are thrown out (not recirculated), causing the cycle to be classified

as an open cycle. The open gas-turbine cycle described above can be modeled as

a closed cycle, as shown in Fig. 1.2, by utilizing the air-standard

assumptions. Here the compression and expansion processes remain the same, but

the combustion process is replaced by a constant-pressure heat-addition process

from an external source, and the exhaust process is replaced by a constant

pressure heat-rejection process to the ambient air. The ideal cycle that the

working fluid undergoes in this closed loop is the Brayton cycle, which

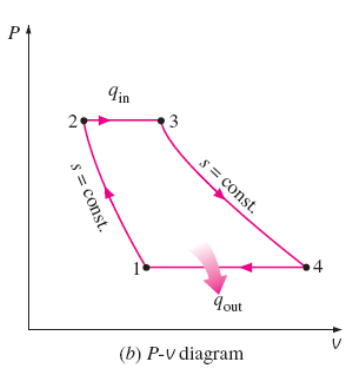

is made up of four internally reversible processes:

- 1-2 Isentropic

compression (in a compressor)

- 2-3

Constant-pressure heat addition

- 3-4 Isentropic

expansion (in a turbine)

- 4-1

Constant-pressure heat rejection

FIGURE 1.1. OPEN CYCLE GAS TURBINE

FIGURE

1.2. CLOSED-CYCLE GAS TURBINE

FIGURE 1.3(a). TEMPERATURE-ENTROPY DIAGRAM FOR BRAYTON CYCLE

FIGURE 1.3 (b).

PRESSURE-VOLUME DIAGRAM FOR BRAYTON CYCLE

2.

Brayton Cycle Temperature: The highest

temperature in the cycle occurs at the end of the combustion process (state 3),

and it is limited by the maximum temperature that the turbine blades can

withstand. This also limits the pressure ratios that can be used in the cycle.

There should be a compromise between the pressure ratio (thus the thermal

efficiency) and the net work output. With less work output per cycle, a larger

mass flow rate (thus a larger system) is needed to maintain the same power

output, which may not be economical. In most common designs, the pressure ratio

of gas turbines ranges from about 11 to 16.

3.

Air in Gas Turbines: The air in gas

turbines performs two important functions: It supplies the necessary oxidant

for the combustion of the fuel, and it serves as a coolant to keep the

temperature of various components within safe limits. The second function is

accomplished by drawing in more air than is needed for the complete combustion

of the fuel. In gas turbines, an air–fuel mass ratio of 50 or above is not

uncommon. Therefore, in a cycle analysis, treating the combustion gases as air

does not cause any appreciable error. Also, the mass flow rate through the

turbine is greater than that through the compressor, the difference being equal

to the mass flow rate of the fuel. Thus, assuming a constant mass flow rate

throughout the cycle yields conservative results for open-loop gas-turbine

engines.

4.

Main Applications of Open-Cycle Gas

Turbines: The

two major application areas of gas-turbine engines are aircraft propulsion and

electric power generation. When it is used for aircraft propulsion, the

gas turbine produces just enough power to drive the compressor and a small

generator to power the auxiliary equipment. The high-velocity exhaust gases are

responsible for producing the necessary thrust to propel the aircraft.

5.

Combined-Cycle Gas Turbines: Gas

turbines are also used as stationary power plants to generate electricity as

stand-alone units or in conjunction with steam power plants on the

high-temperature side. In these plants, the exhaust gases of the gas turbine

serve as the heat source for the steam.

6.

Closed-Cycle, Helium, Gas Turbines: The

gas-turbine cycle can also be executed

as a closed cycle for use in nuclear power plants. This time the working fluid

is not limited to air, and a gas with more desirable characteristics (such as

helium) can be used.

7.

The majority of the Western world’s

naval fleets already use gas-turbine engines for propulsion and electric power

generation. The General Electric LM2500 gas turbines used to power ships have a

simple-cycle thermal efficiency of 37 percent. Many modern marine propulsion

systems use gas turbines together with diesel engines because of the high fuel

consumption of simple-cycle gas-turbine engines. In combined diesel and

gas-turbine systems, diesel is used to provide for efficient low-power and

cruise operation, and gas turbine is used when high speeds are needed.

8.

The General Electric WR-21 gas turbines

equipped with inter-cooling and regeneration have a thermal efficiency of 43

percent and produce 21.6 MW (29040 hp). The regeneration also reduces the

exhaust temperature from 600°C to 350°C. Air is compressed to 3 atm before it

enters the intercooler. Compared to steam-turbine and diesel propulsion

systems, the gas turbine offers greater power for a given size and weight, high

reliability, long life, and more convenient operation. The engine start-up time

has been reduced from 4 h required for a typical steam propulsion system to

less than 2 min for a gas turbine.

9. In

gas-turbine power plants, the ratio of the compressor work to the turbine work,

called the back work ratio, is very high. Usually more than one-half of

the turbine work output is used to drive the compressor. The situation is even

worse when the isentropic efficiencies of the compressor and the turbine are

low. This is quite in contrast to steam power plants, where the back work ratio

is only a few percent. This is not surprising, however, since a liquid is

compressed in steam power plants instead of a gas, and the steady-flow work is

proportional to the specific volume of the working fluid. A power plant with a

high back work ratio requires a larger turbine to provide the additional power

requirements of the compressor. Therefore, the turbines used in gas-turbine

power plants are larger than those used in steam power plants of the same net

power output.

SECTION TWO: DEVELOPMENTS IN BRAYTON CYCLE FOR

GAS TURBINES

The gas turbine has experienced

phenomenal progress and growth since its first successful development in the

1930s. The early gas turbines built in the 1940s and even 1950s had simple

cycle efficiencies of about 17 percent because of the low compressor and

turbine efficiencies and low turbine inlet temperatures due to metallurgical

limitations of those times. Therefore, gas turbines found only limited use

despite their versatility and their ability to burn a variety of fuels. The

efforts to improve the cycle efficiency concentrated in three areas:

1. Increasing the turbine

inlet (or firing) temperatures This has

been the primary approach taken to improve gas-turbine efficiency. The turbine

inlet temperatures have increased steadily from about 540°C in the 1940s to

1425°C and even higher today. These increases were made possible by the

development of new materials and the innovative cooling techniques for the

critical components such as coating the turbine blades with ceramic layers and

cooling the blades with the discharge air from the compressor. Maintaining high

turbine inlet temperatures with an air-cooling technique requires the

combustion temperature to be higher to compensate for the cooling effect of the

cooling air. However, higher combustion temperatures increase the amount of

nitrogen oxides (NOx), which are responsible for the formation of ozone

at ground level and smog. Using steam as the coolant allowed an increase in the

turbine inlet temperatures by 200°F without an increase in the combustion

temperature. Steam is also a much more effective heat transfer medium than air.

2. Increasing the

efficiencies of turbomachinery components: The

performance of early turbines suffered greatly from the inefficiencies of

turbines and compressors. However, the advent of computers and advanced

techniques for computer-aided design made it possible to design these

components aerodynamically with minimal losses. The increased efficiencies of

the turbines and compressors resulted in a significant increase in the cycle

efficiency.

3. Adding modifications to

the basic cycle: The simple-cycle

efficiencies of early gas turbines were practically doubled by incorporating

inter-cooling, regeneration (or recuperation), and reheating, discussed in the

next two sections. These improvements, of course, come at the expense of

increased initial and operation costs, and they cannot be justified unless the

decrease in fuel costs offsets the increase in other costs. The relatively low

fuel prices, the general desire in the industry to minimize installation costs,

and the tremendous increase in the simple-cycle efficiency to about 40 percent

left little desire for opting for these modifications. The first gas turbine

for an electric utility was installed in 1949 in Oklahoma as part of a

combined-cycle power plant. It was built by General Electric and produced 3.5

MW of power. Gas turbines installed until the mid-1970s suffered from low

efficiency and poor reliability. In the past, the base-load electric power

generation was dominated by large coal and nuclear power plants.

4.

Shift to Natural Gas-fired

gas turbines: There has been a historic shift toward natural gas–fired gas

turbines because of their higher efficiencies, lower capital costs, shorter

installation times, and better emission characteristics, and the abundance of

natural gas supplies, and more and more electric utilities are using gas

turbines for base-load power production as well as for peaking. The construction

costs for gas-turbine power plants are roughly half that of comparable

conventional fossil-fuel steam power plants, which were the primary base-load

power plants until the early 1980s. More than half of all power plants to be

installed in the foreseeable future are forecast to be gas turbine or combined

gas–steam turbine types.

5. Example of increase in efficiency and power of gas turbines: A gas

turbine manufactured by General Electric in the early 1990s had a pressure

ratio of 13.5 and generated 135.7 MW of net power at a thermal efficiency of 33

percent in simple-cycle operation. A more recent gas turbine manufactured by

General Electric uses a turbine inlet temperature of 1425°C and produces up to

282 MW while achieving a thermal efficiency of 39.5 percent in the simple-cycle

mode. A 1.3-ton small-scale gas turbine labeled OP-16, built by the Dutch firm

Opra Optimal Radial Turbine, can run on gas or liquid fuel and can replace a

16-ton diesel engine. It has a pressure ratio of 6.5 and produces up to 2 MW of

power. Its efficiency is 26 percent in the simple-cycle operation, which rises

to 37 percent when equipped with a regenerator.

SECTION

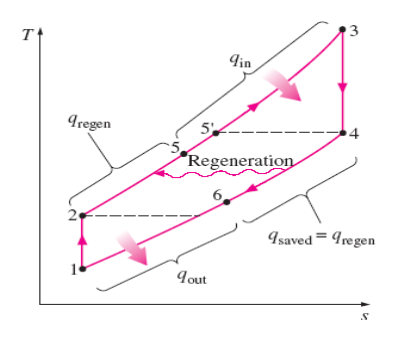

THREE: THE BRAYTON CYCLE WITH REGENERATION

In gas-turbine engines, the

temperature of the exhaust gas leaving the turbine is often considerably higher

than the temperature of the air leaving the compressor. Therefore, the high

pressure air leaving the compressor can be heated by transferring heat to it

from the hot exhaust gases in a counter-flow heat exchanger, which is also

known as a regenerator or a recuperator. A sketch

of the gas-turbine engine utilizing a regenerator and the T-s diagram

of the new cycle are shown in in the figures below:

The thermal efficiency of

the Brayton cycle increases as a result of regeneration since the portion of

energy of the exhaust gases that is normally rejected to the surroundings is

now used to preheat the air entering the combustion chamber. This, in turn,

decreases the heat input (thus fuel) requirements for the same net work output.

Note, however, that the use of a regenerator is recommended only when the

turbine exhaust temperature is higher than the compressor exit temperature.

Otherwise, heat will flow in the reverse direction (to the exhaust

gases), decreasing the efficiency. This situation is encountered in gas-turbine

engines operating at very high pressure ratios.

The highest temperature occurring within the

regenerator is T4, the temperature of the exhaust gases leaving the

turbine and entering the regenerator. Under no conditions can the air be

preheated in the regenerator to a temperature above this value. Air normally

leaves the regenerator at a lower temperature, T5. In the limiting

(ideal) case, the air exits the regenerator at the inlet temperature of the

exhaust

SECTION

FOUR: THE BRAYTON CYCLE WITH INTERCOOLING, REHEATING, AND REGENERATION

4.1.

Multistage Compression with

Intercooling: The net work of a gas-turbine cycle

is the difference between the turbine work output and the compressor work

input, and it can be increased by either decreasing the compressor work or

increasing the turbine work, or both. As mentioned before that the work

required to compress a gas between two specified pressures can be decreased by

carrying out the compression process in stages and cooling the gas in between

—that is, using multistage compression with intercooling. As the number of stages is increased, the

compression process becomes nearly isothermal at the compressor inlet temperature,

and the compression work decreases.

4.2.

Multistage Expansion with

re-heating: Likewise, the work output of a

turbine operating between two pressure levels can be increased by expanding the

gas in stages and reheating it in between—that is, utilizing multistage

expansion with reheating. This is accomplished without raising the maximum

temperature in the cycle. As the number of stages is increased, the expansion

process becomes nearly isothermal. The foregoing argument is based on a simple

principle:

4.3.

Intercooling and

Re-heat: The steady-flow compression or expansion work is proportional to

the specific volume of the fluid. Therefore, the specific volume of the working

fluid should be as low as possible during a compression process and as high as

possible during an expansion process. This is

precisely what intercooling and reheating accomplish. Combustion in gas

turbines typically occurs at four times the amount of air needed for complete

combustion to avoid excessive temperatures. Therefore, the exhaust gases are

rich in oxygen, and reheating can be accomplished by simply spraying additional

fuel into the exhaust gases between two expansion states.

The working fluid leaves the

compressor at a lower temperature, and the turbine at a higher temperature,

when intercooling and reheating are utilized. This makes regeneration more

attractive since a greater potential for regeneration exists. Also, the gases

leaving the compressor can be heated to a higher temperature before they enter

the combustion chamber because of the higher temperature of the turbine

exhaust.

A schematic of the physical arrangement and the T-s diagram

of an ideal two-stage gas-turbine cycle with intercooling, reheating, and

regeneration are shown in the figures below:

FIGURE 4(a). DIAGRAM OF TWO STAGE TURBINE WITH INTERCOOLING, REHEATING AND REGENERATION

FIGURE 4(b). TEMPERATURE/ENTROPY DIAGRAM, TWO STAGE TURBINE WITH INTERCOOLING, REHEATING AND REGENERATION

The gas enters the first stage of the compressor at state 1, is

compressed isentropically to an intermediate pressure P2, is cooled at

constant pressure to state 3 (T3 = T1), and is compressed in the

second stage isentropically to the final pressure P4. At state 4 the gas

enters the regenerator, where it is heated to T5 at constant pressure.

In an ideal regenerator, the gas leaves the regenerator at the temperature of

the turbine exhaust, that is, T5 = T9. The primary heat addition

(or combustion) process takes place between states 5 and 6. The gas enters the

first stage of the turbine at state 6 and expands isentropically to state 7,

where it enters the reheater. It is reheated at constant pressure to state 8 (T8

= T6), where it enters the second stage of the turbine. The gas exits

the turbine at state 9 and enters the regenerator, where it is cooled to state

10 at constant pressure. The cycle is completed by cooling the gas to the

initial state (or purging the exhaust gases).

SECTION

FIVE: IDEAL JET-PROPULSION CYCLES

5.1.

Introduction: Gas-turbine

engines are widely used to power aircraft because they are light and compact

and have a high power-to-weight ratio. Aircraft gas turbines operate on an open

cycle called a jet propulsion cycle. The ideal jet propulsion cycle

differs from the simple ideal Brayton cycle in that the gases are not expanded

to the ambient pressure in the turbine. Instead, they are expanded to a

pressure such that the power produced by the turbine is just sufficient to

drive the compressor and the auxiliary equipment, such as a small generator and

hydraulic pumps. That is, the net work output of a jet propulsion cycle is

zero. The gases that exit the turbine at a relatively high pressure are

subsequently accelerated in a nozzle to provide the thrust to propel the

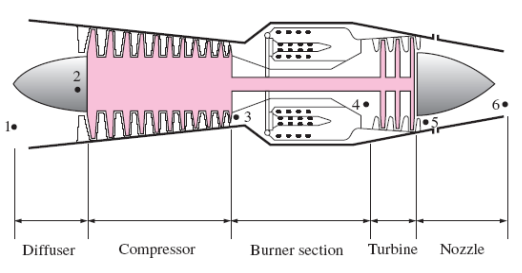

aircraft (See figure below).

Also, aircraft gas turbines operate at higher pressure ratios

(typically between 10 and 25), and the fluid passes through a diffuser first,

where it is decelerated and its pressure is increased before it enters the

compressor. Aircraft are propelled by accelerating a fluid in the opposite

direction to motion. This is accomplished by either slightly accelerating a

large mass of fluid ( propeller-driven engine) or greatly accelerating a

small mass of fluid ( jet or turbojet engine) or both (turboprop

engine). A schematic of a turbojet

engine and the T-s diagram of the ideal turbojet cycle are shown

in the figures below:

FIGURE 5 (a): SCHEMATIC OF A TURBOJET ENGINE

FIGURE 5(b): TEMPERATURE-ENTROPY DIAGRAM FOR THE TURBOJET CYCLE

The pressure of air rises

slightly as it is decelerated in the diffuser. Air is compressed by the

compressor. It is mixed with fuel in the combustion chamber, where the mixture

is burned at constant pressure. The high-pressure and high-temperature

combustion gases partially expand in the turbine,

producing enough power to drive the compressor and other equipment. Finally,

the gases expand in a nozzle to the ambient pressure and leave the engine at a

high velocity. In the ideal case, the turbine work is assumed to equal the

compressor work. Also, the processes in the diffuser, the compressor, the

turbine, and the nozzle are assumed to be isentropic. In the analysis of actual

cycles, however, the irreversibilities associated with these devices should be

considered. The effect of the irreversibilities is to reduce the thrust that

can be obtained from a turbojet engine. The thrust developed in a

turbojet engine is the unbalanced force that is caused by the difference in the

momentum of the low-velocity air entering the engine and the high-velocity

exhaust gases leaving the engine, and it is determined from Newton’s second

law.

SECTION SIX: TURBOFAN ENGINES

The first

airplanes built were all propeller-driven, with propellers

powered by engines essentially identical to automobile engines. The major

breakthrough in commercial aviation occurred with the introduction of the

turbojet engine in 1952. Both propeller-driven engines and jet-propulsion

driven engines have their own strengths and limitations, and several attempts

have been made to combine the desirable characteristics of both in one engine.

The most widely used engine in aircraft propulsion is the turbofan (or fanjet)

engine wherein a large fan driven by the turbine forces a considerable amount

of air through a duct (cowl) surrounding the engine, as shown in the figures

below.

FIGURE

6(a): SCHEMATIC OF A TURBOFAN AIRCRAFT ENGINE

The fan exhaust

leaves the duct at a higher velocity, enhancing the total thrust of the engine

significantly. A turbofan engine is based on the principle that for the same

power, a large volume of slower moving air produces more thrust than a small

volume of fast-moving air.

FIGURE 6(b): SECTION OF A MODERN

TURBOFAN JET ENGINE

The jet engine shown above is used to

power the Boeing 777 aircraft. This is a Pratt & Whitney PW4084 turbofan

capable of producing 84,000 pounds of thrust. It is 4.87 m (192 in.) long, has

a 2.84 m (112 in.) diameter fan, and it weighs 6800 kg (15,000 lbm).

The turbofan engine on an airplane can

be distinguished from the less efficient turbojet engine by its fat cowling

covering the large fan. All the thrust of a turbojet engine is due to the

exhaust gases leaving the engine at about twice the speed of sound. In a

turbofan engine, the high-speed exhaust gases are mixed with the lower-speed

air, which results in a considerable reduction in noise.

New cooling techniques have resulted in

considerable increases in efficiencies by allowing gas temperatures at the

burner exit to reach over 1500°C, which is more than 100°C above the melting

point of the turbine blade materials. Turbofan engines deserve most of the

credit for the success of jumbo jets that weigh almost 400,000 kg and are

capable of carrying over 400 passengers for up to a distance of 10,000 km at

speeds over 950 km/h with less fuel per passenger mile.

The ratio of the mass flow rate of air

bypassing the combustion chamber to that of air flowing through it is called

the bypass ratio. The first commercial high-bypass-ratio engines had a

bypass ratio of 5. Increasing the bypass ratio of a turbofan engine increases

thrust. Thus, it makes sense to remove the cowl from the fan. The result is a propjet

engine.

Turbofan and propjet engines differ

primarily in their bypass ratios: 5 or 6 for turbofans and as high as 100 for

propjets. As a general rule, propellers are more efficient than jet engines,

but they are limited to low-speed and low-altitude operation since their

efficiency decreases at high speeds and altitudes.